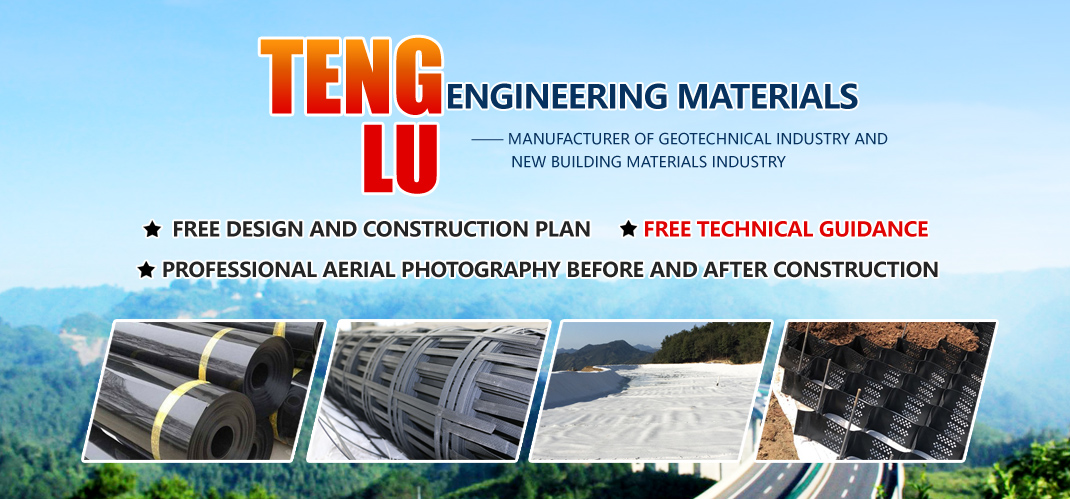

Classification and characteristics of geogrids. Tai'an Tenglu Engineering Materials Co., Ltd. will answer your questions

Geogrids are divided into four categories: plastic geogrids, steel plastic geogrids, fiberglass geogrids and fiberglass polyester geogrids

Fiberglass geogrid features:

(1) High tensile strength and low elongation - glass fiber geogrid is made of glass fiber, which has high deformation resistance and elongation at break less than 3%.

(2) No long-term creep - as a reinforcing material, it is important to have the ability to resist deformation under long-term load, that is, creep resistance, and glass fiber will not creep, which ensures that the product can maintain performance for a long time.

(3) Thermal stability - the melting temperature of glass fiber is above 1000 ℃, which ensures the thermal stability of glass fiber geogrid during paving operations.

(4) Compatibility with asphalt mixture - the material coated by the glass fiber geogrid in the post-treatment process is designed for the asphalt mixture, and each fiber is fully coated and has a high compatibility with asphalt. Capacitive, thus ensuring that the fiberglass geogrid will not be isolated from the asphalt mixture in the asphalt layer, but will be firmly combined.

Steel-plastic composite geogrid features:

1. The tensile force of the steel-plastic composite geogrid is borne by the high-strength steel wire woven by warp and weft, which produces a tensile modulus under low strain capacity, and the longitudinal and transverse ribs cooperate to give full play to the interlocking effect of the grid on the soil.

2. The steel wire of the longitudinal and transverse ribs of the steel-plastic composite geogrid is warp and weft woven into a mesh, the outer wrapping layer is formed at one time, the steel wire and the outer wrapping layer can coordinate, and the elongation at failure is very low (not more than 3%). The main force-bearing unit of the steel-plastic composite geogrid is steel wire, and the creep value is low.

3. Through the treatment of the plastic surface in the production process, rough patterns are pressed to enhance the roughness of the grid surface and improve the friction coefficient between the steel-plastic composite geogrid and the soil.

4. The width of the steel-plastic composite geogrid can reach 6m to achieve economical reinforcement effect.

5. The high-density polyethylene used in the steel-plastic composite geogrid can ensure that it will not be eroded by acid-base and salt solutions, or oil at room temperature; it will not be attacked by water dissolution or microorganisms. At the same time, the polymer properties of polyethylene are also sufficient to resist the aging caused by ultraviolet radiation. After the grating is stressed, the longitudinal and transverse ribs act synergistically, and there will be no cracking or damage of the nodes. In actual engineering, after the packing is compacted, it is not exposed to ultraviolet light and oxygen.

Polyester geogrid features:

1. The warp knitting directional structure is adopted, and the warp and weft yarns in the fabric are not bent with each other, and the intersections are bundled and combined with high-strength fiber filaments to form a firm joint and give full play to its mechanical properties.

2. High-strength polyester fiber warp-knitted geogrid has high tensile strength, small elongation force, large tear resistance strength, and small difference in vertical and horizontal strength.

3. Anti-ultraviolet aging, wear resistance, corrosion resistance, light weight, and strong interlocking force with soil or gravel, it has a significant effect on enhancing the shear resistance and reinforcement of the soil body and improving the integrity and load capacity of the soil body. High tensile strength, high tear strength, and strong binding force with soil and gravel.

Plastic geogrid features:

1. The polymer is in a directional linear state and forms a long elliptical network integral structure with uniform distribution and high node strength. This structure has a relatively high tensile strength and rigidity, which provides the soil with an ideal interlocking system for force bearing and diffusion.

2. The outstanding advantage of one-way plastic geogrid is that it has a small tendency to deform (creep) under long-term continuous load, and its creep resistance is much better than that of geogrids of other materials, which plays an important role in improving the service life of the project. .

3. The occlusion and interlocking between the grid mesh and the soil constitute a stress transmission mechanism, so that the local load can be quickly and effectively diffused into the large area of the soil, thereby reducing the local failure stress and improving the The purpose of the service life of the project.