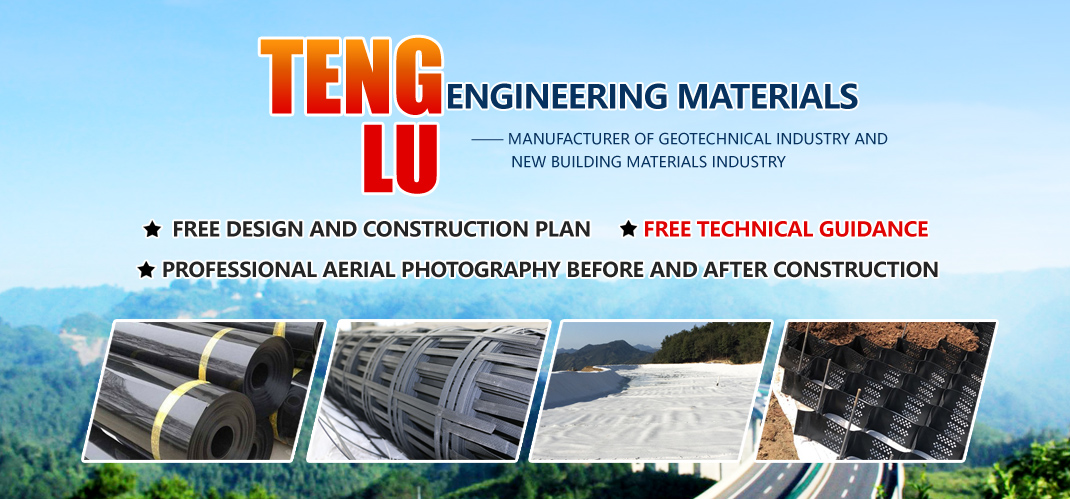

Tai'an Teng Road Engineering Materials Co., Ltd. shares the details of the construction method of geomembrane:

When laying the film, it must be laid from top to bottom. The film and the film and between the film and the base surface should be pressed flat and tightly, but the film should not be pulled too tightly. Generally, it should be slightly loose, but there should be no air bubbles at the bottom of the film. Because the geomembrane is relatively thin and light, it is very easy to be blown by the wind before the protective layer is laid after it is laid, so the area of one laying membrane should not be too large, and the protective layer should be covered while laying the membrane.

The soil material of the 10cm thick protective layer of the geomembrane must be sieved, and no particles with a particle size larger than 6mm are not allowed, otherwise the geomembrane will be easily pierced. The soil material of the protective layer must be compacted by tamping to ensure that the dry bulk density is above 1.5, and sampling inspection shall be conducted at any time. When backfilling the protective layer and building block stone protective surface, it must be handled lightly to avoid breaking the geomembrane. Under the block stone protective surface, a 100mm thick gravel or gravel cushion should be laid to prevent the soil protection layer from being washed away due to the influence of water level changes, wind and waves and other factors. Dry masonry blocks shall be paved with artificial hanging lines, the blocks shall be tightly embedded, the individual weight of the surface blocks shall be greater than 48kg, and all gaps shall be filled with small blocks.

Guards and protective layers. The clay used to protect the geomembrane must be sieved to remove large particles with a particle size of more than 6mm to avoid puncturing the geomembrane. After the soil material is laid, it should be hit and compacted to ensure that the dry bulk density is higher than 1.5, and the samples should be sent to the laboratory for testing. In the process of backfilling the protective layer and building the lake surface, be sure to handle it gently, otherwise the membrane will be broken. A cushion layer with a thickness of 100mm needs to be filled under the protective surface to avoid the protective layer being washed out due to changes in the water level. The dry masonry stones should be paved by artificially hanging lines, the stones should be tightly embedded and the voids should be filled with small stones or stone chips.

Geomembrane construction method details Geomembrane has excellent anti-seepage performance, stability, and can be processed according to actual engineering needs and functions, has been widely used in environmental sanitation, solid waste landfill, and other fields, but you know Are there detailed rules for the construction method of geomembrane? Everyone has a chance to know now.

1. Technological process. The composite geomembrane anti-seepage of the Zhoutou Reservoir dam adopts the section cycle work of digging, laying, ramming, and protecting

2. Laying geomembrane: in the process of laying the membrane, it should be carried out in the order from bottom to top. The two adjacent geomembranes and the geomembrane and the base surface must be flattened and closely attached, but be careful not to pull too tightly, and it is advisable to have no air bubbles.

3. Base surface cleaning. The base surface must be cleaned according to the design requirements, which is the pivot to ensure the anti-seepage effect, especially the debris such as sharp stones and tree roots should be thoroughly removed, and the base surface should not have local unevenness. The cleaned base surface should be tamped with a tamper or a tamper to make it compact and flat.

4, junction processing. The purpose of the junction treatment is to ensure a good connection between the soil mass and the geomembrane, and to block the inlet of seepage, cut off all lateral leakage paths, and prevent seepage water from entering the bottom of the membrane, causing blisters to form at the bottom and causing the geomembrane to rupture. Based on this, in the actual construction, the intercepting groove should be excavated according to the requirements, and the geomembrane should be buried in the groove at the same time.

5. Laying of composite geomembrane. When laying geomembrane, it must be laid from top to bottom.

6. The relevant information provided, this construction adopts a width of 6m to reduce the number of joints. As for the joint, it can be lap joint, or hot glued or glued. In this project, lap joint is adopted, and the seam width is 20cm.

7. Peripheral junction treatment. The requirement of peripheral junction treatment is to tightly connect the geomembrane with the surrounding soil, block the seepage inlet, cut off the lateral leakage path, and prevent the seepage from entering the bottom surface of the geomembrane, forming blisters, and at the reservoir water level When falling, the geomembrane is swelled. The joints have methods such as thermal bonding, gluing, and lap jointing. The design of this project adopts gluing, and the joint width is 50mm.

8. Base surface treatment: Thoroughly clean the base surface according to the design requirements, which is the key to making the geomembrane play a good anti-seepage role, especially to clean up tree roots and sharp stones, and the base surface must not have undulations. After cleaning, tamp it to ensure that Flatness and compaction.

9. Protective layer and protective surface. The soil material of the protective layer with a thickness of 10 cm by the geomembrane must be sieved, and no particles with a particle size larger than 6 mm are allowed, otherwise the geomembrane will be easily pierced. Because the geomembrane is relatively thin and light After it is finished, before the protective layer is laid, it is very easy to be blown by the wind, so the area of the film should not be too large at one time, and it is better to cover the protective layer soil material while laying the film. Therefore, it should not be too long to lay the film at one time, and cover it with soil material while laying the film.